3DQF Library

PLA Easy Start Guide

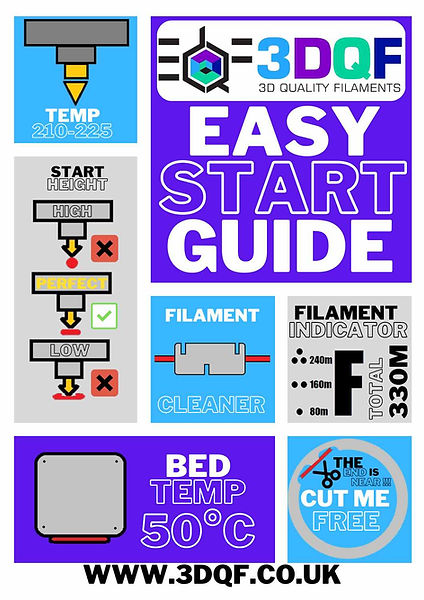

3DQF PLA Printing Easy Start Guide

Welcome to the world of 3D printing with 3DQF PLA! We are here to provide you with a comprehensive guide to help you get started on your 3D printing journey. Whether you are a beginner or an experienced user, we aim to make this process as smooth and enjoyable as possible. If you encounter any issues or need assistance, please don't hesitate to contact our UK customer service team for help at any time.

Contact Information:

Phone: 01942 644000

Email: Sales@3Dqualityfilaments.co.uk

Important Reminders:

Firstly remember that patience and practice are key to successful 3D printing. You are starting at the bottom of a steep learning curve with one of the most challenging steps of bed adhesion needing to be accomplished first.

Make sure to read and follow the instructions provided with your 3D printer and use these and other guides as a reference for personal development.

Filament Temperature:

The optimal hot-end temperature for our 3DQF PLA is 210-225°C. It's our recommendation to start within this range for your first prints. Most imported filaments work at a lower temperature than ours due to fillers and additives. Its completely normal to need a little more heat with our PLA material as we keep it simple with no fillers or bulking agents just pure Natureworks material.

The maximum safe hot-end temperature for 3DQF PLA is 225°C (printing at a speed of up to 120mm per second 'mm/p').

Please avoid exceeding this temperature limit if you print below a speed of 120 mm/s.

Highspeed printing is now a thing, and with increased speed comes the need for higher temperatures to help the material flow. We have another guide for High-speed printing. If you attempting to use our filament in a high-speed printer please head over to the "High-speed printing" guide for recommendations on printing temps.

Bed Temperature:

We recommend 3DQF PLA heated bed temperature no hotter than 50°C. This ensures proper adhesion while preventing excessive warping or deformation. Running hotter bed temperatures will not help with bed adhesion, in-fact cooling down the bed will be more of a benefit. If you are struggling to get the filament to stick have a search for our z-off-set guide which will more than likely be the issue. Do not under estimate how important a flat and level bed that had been trammed to the extruder's gantry is. A truly trammed bed and gantry will make setting your z-off-set so much simpler.

Cut me free before I run out:

During the design process, we knew our spool should release the filament cleanly at the end of the roll. To allow this to happen we loop the end of the roll outside the spool so you can snip it free prior to running out. This means it will allow the tail of the filament to release cleanly at the end of the roll, and through your run-out detector (if fitted) pausing your print. Commonly on imported filament on a plastic spool, you can't get to the tail of the filament and this will normally cause no end worth of issues as it generally won't release cleanly from the spool.

Filament cleaner

Cleaning filament is so important, we find that filament tends to stand around for a while. This will cause a build-up of dust on the surface, this is then dragged into the extruder and could cause a blockage over time. To combat this we recommend a cleaner to wipe the filament just before it enters the PTFE tube or extruder. This can be as simple as a small section of foam to just act as a wiper.

Dont forget if you need some more assistance drop us a call, we will be happy to offer assistance.